Life Sciences & Labs Construction

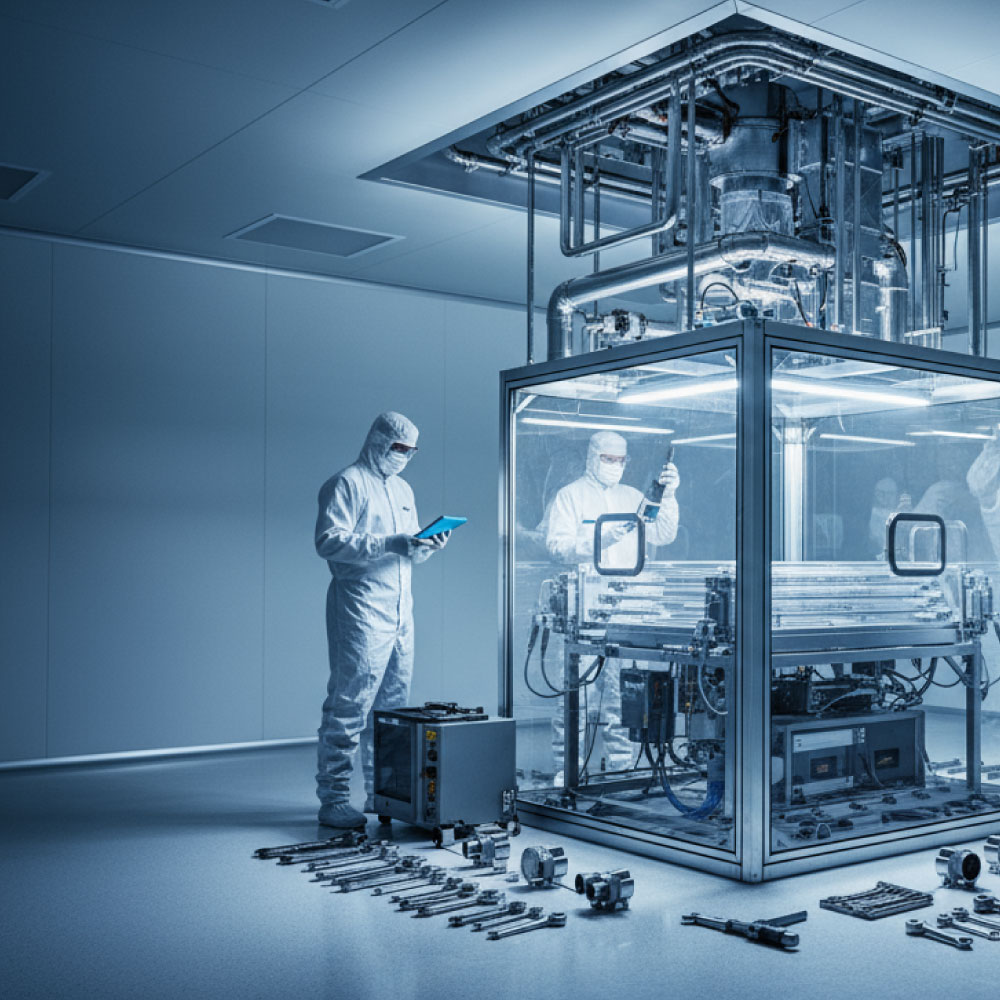

Cleanrooms, laboratories and research spaces delivered in live estates with sealed zones, integrated MEP, fume extraction and validation-led, clean commissioning for predictable handover.

- Home

- Construction

- Life sciences & labs

Life sciences & labs — cleanrooms, laboratories & controlled environments

We deliver new build and live-estate refurbishments for pharma, biotech and academia with sealed zones, negative-pressure segregation and clean-build protocols. Wet labs, dry labs and GMP suites are coordinated end-to-end with integrated MEP, fume extraction and LEV, gas services, power/ICT containment and BMS trending for compliant, predictable handovers.

Typical scopes include cleanrooms (ISO 14644), fume cupboards and extract, write-up and support spaces, autoclaves and specialist services, plant upgrades (AHUs, filtration, DHW/steam), fire strategy integration and validation evidence packs aligned to your QA framework.

Sealed containment, clean installs and validation-led commissioning for a spotless, compliant handover.

Key features

Sealed zones & contamination control

Negative/positive pressure regimes, airlocks, sticky mats and clean-down protocols to protect works and operations.

Integrated MEP for labs

Ventilation & filtration (HEPA), LEV & fume extract, gases, RO/DI water, power/ICT containment and BMS integration.

Compliance & validation

Design to ISO 14644 principles and GMP expectations with FAT/SAT support, IQ/OQ documentation and calibration records.

Programme certainty

Two-stage planning, clear gateways and weekly look-aheads with early ordering of specialist equipment and filters.

Clean build & quality control

ITPs and hold points, controlled material handling, particulate monitoring and digital QA evidence during install.

Commissioning & handover

Airflow balancing, leakage testing, room performance testing and complete O&M packs for a clean, compliant handover.

0+

Projects Delivered0+

Live-Environment Shifts / Yr0+

Sectors Served0+

Years of DeliveryFrom preconstruction to clean handover

We plan, build, and commission complex projects in live and new environments with integrated MEP and rigorous QA.

Trusted construction partner for complex delivery

Programme control

Two-stage planning, gateways, risk logs and weekly look-aheads that keep dates predictable and stakeholders aligned.

Live environment expertise

Phasing, red and blue routes, sealed zones and night windows so buildings stay operational without unplanned downtime.

Integrated MEP

Early coordination, prefab where viable, staged changeovers and rollback plans that protect services during cutover.

Clean commissioning & validation

ITPs and hold points, flushing and balancing, IST and vendor sign-off. HTM/HBN for healthcare and Tier-readiness for data halls.

Digital QA & golden thread

Photo evidence, inspections, product data and change control captured to produce clear O&M packs and Building Safety Act gateways.

Safety first

RAMS and permits, CDM duties, environmental controls and third-party audits. We aim for zero incidents and zero rework.

Peace of mind on complex builds Peace of mind on complex builds

projects delivered

From preconstruction to clean handover we plan risks early, coordinate MEP with precision and capture digital QA evidence so your programme stays predictable and compliant. We set out clear gateways, publish weekly look-aheads and risk logs so nothing drifts. Staged changeovers, clean commissioning and soft landings give you a smooth, defect-free handover.

25

Live ward refurbishment delivered in night windows with red/blue routes and negative pressure—zero unplanned disruption to care.

Deputy Director of Estates, NHS TrustHTM/HBN requirements were built into design and sign-offs from day one. The evidence pack made approvals swift and defensible.

Head of Capital Projects, Acute HospitalComplex MEP changeover completed with prefabricated skids and staged commissioning—clean, compliant and ahead of programme.

Engineering Manager, Teaching HospitalTheir programme control was exemplary—transparent look-aheads, risk logs and gateways that kept stakeholders aligned throughout.

Project Director, Commercial DevelopmentTheatre laminar-flow works under sealed containment were executed flawlessly—IPC sign-offs first time, no rework.

Infection Prevention & Control Lead, NHSPreconstruction clarified risks early—cost plan, buildability and phasing turned a complex brief into a predictable delivery.

Development Manager, Private HealthcareData-centre fit-out with integrated MEP and QA—clean rooms, spotless containment and handover with zero defects.

Programme Lead, Technology ClientFramework navigation was refreshingly simple—Procure23 route, governance and approvals explained and actioned without delay.

Head of Procurement, NHS Integrated Care BoardIntegrated delivery for live, critical environments

Clear steps to a clean handover

Preconstruction brief

Scope, gateways and programme outline with risks and cost assumptions set out early.

Design & procurement

Coordinated design, CDP, and long-lead items locked to protect the critical path.

Construction & phasing

Live-environment controls, integrated MEP install and weekly look-aheads on site.

Commissioning & handover

ITPs, witness tests and digital QA packs delivered to a clean, defect-free handover.

Everything you should know about Construction

- Construction

-

What types of projects do you deliver?New build, refurbishment and fit-out across education, commercial offices, industrial and logistics, life sciences and data centres with programme-led delivery and integrated trades.How do you keep programmes predictable?Two-stage planning with gateways, look-ahead schedules, risk and issue logs, and weekly progress reviews. Early procurement of long-lead items and clear change control prevent drift.How do you work in live or occupied buildings?Phasing and decant plans, out-of-hours windows, red and blue routes, dust and noise controls, compliant hoardings, permits to work and daily briefings so operations continue safely.Do you support preconstruction and design?Yes. Feasibility, surveys, cost planning, value engineering and buildability reviews with clear assumptions and constraints. We coordinate design to de-risk site delivery.How do you manage quality and handover?ITPs and hold points, digital QA evidence with photos and certificates, progressive snag closure, commissioning plans and soft landings. Complete O&M packs for a clean handover.Which procurement routes do you work under?Two-stage and single-stage D&B, traditional, and PCSA arrangements. We also deliver through client frameworks where required with open-book options available.How do you manage health, safety and environment?CDM compliance, RAMS and permits, inductions and daily briefings, temporary works control, environmental protection and independent audits. We target zero incidents and zero rework.Do you use prefabrication or DFMA?Yes where it adds value. We assess skids, risers and modular elements during preconstruction to improve quality, reduce time on site and minimise disruption in live environments.How do you handle cost control and changes?Baseline cost plans with tracked assumptions, live change registers, priced options and approvals before issue. Forecasts are updated with each gateway so budgets stay under control.What support do we get after completion?Training and soft landings, defects response with clear SLAs, seasonal commissioning if needed, and retained records to maintain the golden thread for the asset lifecycle.